|

|

Ajax TOCCO Induction Services...The Difference is Apparent

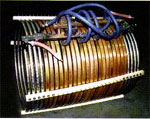

Heat Treating Coils

We have developed the special expertise to design, build and repair any size, shape or form of coils used for hardening, annealing, tempering and other heat treating and selective heating processes. necessary machine tools, materials and skilled craftsmen (yes, "craftsmen!") have been refined over the 21 years in the induction coil business. Coils and tooling for all types of induction heat treating applications are processed regularly. Quick disconnect coil adapters and water cooled bus can be supplied to suit your existing equipment. Coil laminations and other flux concentrator materials can be designed and fabricated for your specific application. Quench Chambers, rings and blocks are repaired and/or replaced if necessary.

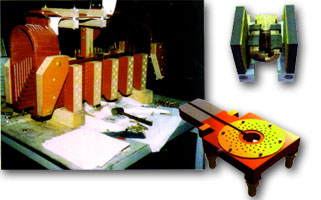

Heating Coils

Put our experience to work for you. We can provide reduced overall costs compared to "in-house" coil repairs. Bar and billet heating coils that last longer save you money and reduce downtime. In-line heating coils for tube, wire, coating, annealing, etc., are rebuilt using a variety of construction methods. All types and manufacturer's coils can be repaired, rebuilt or modified including European coils. All styles of coils including cast refractory block type, 60 Hz tie-rod type, replaceable cast liners and open winding type with aluminum framework are regularly rebuilt. Our extensive experience and research in insulation coatings and refractories allow us to quickly rebuild and/or recommend improvements for increased efficiency or service life.

|

®

®

®

® ®

®